Galvanized Steel Flashing Thickness: Choosing the Right Gauge

When it comes to protecting your home or building from water damage, proper flashing installation is crucial. Galvanized steel flashing is a popular choice due to its durability and resistance to corrosion. However, choosing the right gauge of galvanized steel flashing is equally important to ensure optimal performance.

What is Galvanized Steel Flashing?

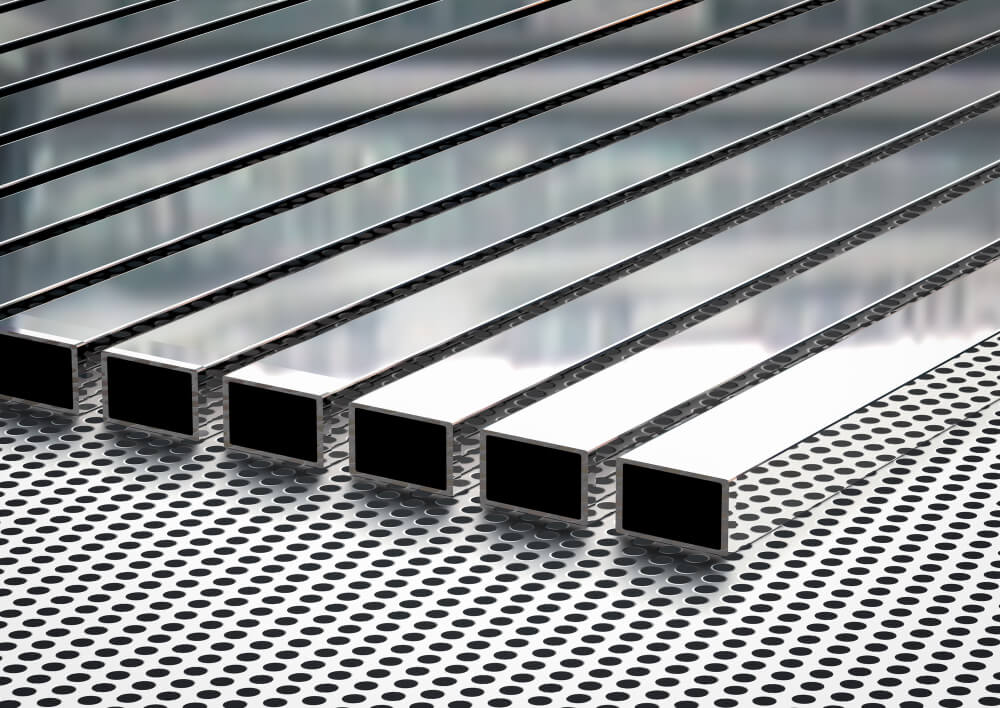

Galvanized steel flashing refers to thin metal strips or sheets made from steel that has been coated with a layer of zinc. This coating protects the underlying steel from rust and corrosion, extending its lifespan significantly. The galvanization process involves immersing the steel in a bath of molten zinc, forming a strong bond between the two materials.

Importance of Flashing in Construction

Flashings play a vital role in preventing water intrusion into buildings. They are installed in vulnerable areas, such as roof edges, windows, doors, and intersections between different building components. By redirecting water away from these critical junctures, flashing helps maintain the integrity of the structure and prevents costly water damage, mold growth, and rot.

In the context of galvanized steel flashing, gauge refers to the measurement of thickness. However, gauge measurements can be counterintuitive. The lower the gauge number, the thicker the steel. For example, 26-gauge steel is thicker than 29-gauge steel. It’s important to grasp this concept when choosing the appropriate gauge for your flashing needs.

Factors to Consider When Choosing the Right Gauge

1. Climate and Weather Conditions

The climate and weather conditions of your region play a significant role in determining the appropriate gauge for your galvanized steel flashing. In areas prone to severe weather, such as heavy rainfall or high winds, thicker gauges like 24 or 26 can provide enhanced protection against potential damage.

2. Building Design and Structure

The design and structure of your building also influence the gauge selection. Factors such as the roof pitch, type of roof covering, and architectural complexity can impact the amount of water exposure and potential stress on the flashing. Buildings with steeper roofs or complex geometries may require thicker gauges to ensure sufficient durability and performance.

3. Manufacturer Recommendations

Always consult the manufacturer’s recommendations and guidelines when choosing the right gauge for galvanized steel flashing. Manufacturers often conduct extensive testing and research to determine the optimal thicknesses for different applications. Following their recommendations ensures that you select the gauge that meets the required industry standards and provides adequate protection for your specific project.

Common Gauges Used in Galvanized Steel Flashing

1. 29 Gauge:

29-gauge galvanized steel flashing is commonly used for residential applications. It is thinner and more flexible, making it suitable for simpler roof designs or areas with less severe weather conditions. However, it may not offer the same level of protection as thicker gauges in regions with harsh climates.

2. 26 Gauge:

26-gauge galvanized steel flashing strikes a balance between flexibility and durability. It is often preferred for residential and light commercial buildings. This gauge provides increased strength and better resistance against potential damage from weather elements, making it suitable for a wider range of applications.

3. 24 Gauge:

24-gauge galvanized steel flashing is the thickest commonly available gauge. It offers excellent strength and durability, making it suitable for structures exposed to extreme weather conditions or buildings with complex designs. This gauge provides maximum protection and is commonly used in commercial and industrial settings.

Gauge Selection and Installation

Choosing the right gauge and installing galvanized steel flashing require knowledge and expertise. It is advisable to consult with a professional contractor or a qualified expert who can assess your specific requirements accurately. They will consider all relevant factors and ensure compliance with local building codes, ensuring a successful and effective flashing installation.

In conclusion, selecting the appropriate gauge for galvanized steel flashing is a critical decision that impacts the overall effectiveness of your building’s waterproofing system. Factors such as climate, building design, and manufacturer recommendations should be considered when making this choice. By investing in the right gauge of galvanized steel flashing, you can protect your property from water damage, maintain structural integrity, and ensure long-lasting durability. Consult with a professional to guide you through the gauge selection and installation process, ultimately safeguarding your investment in the construction or renovation project.