PANEL

Master Panel offers our clients a technical department to support your designers and Project Management. Our building system section provides support from the initial concept of the project to the installation and subsequent maintenance.

- Proposals for appropriate technical solutions for each project.

- Providing support regarding the cutting, quantifications of the panels and necessary accessories.

- Support and technical information for the training of fitters.

- We provide plans and sketches of the most common technical details.

- Technical support in the correct installation of our panels, forming a team with the Project Management

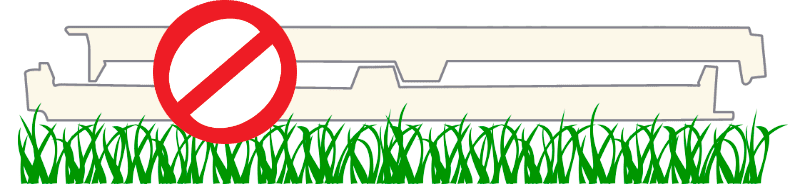

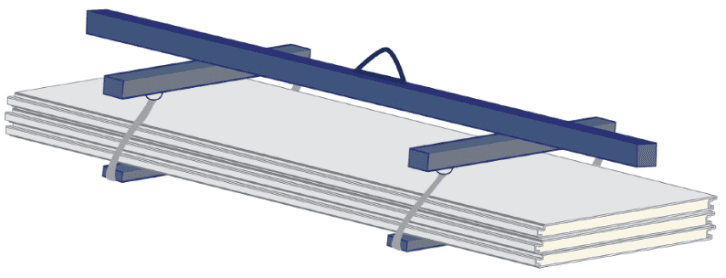

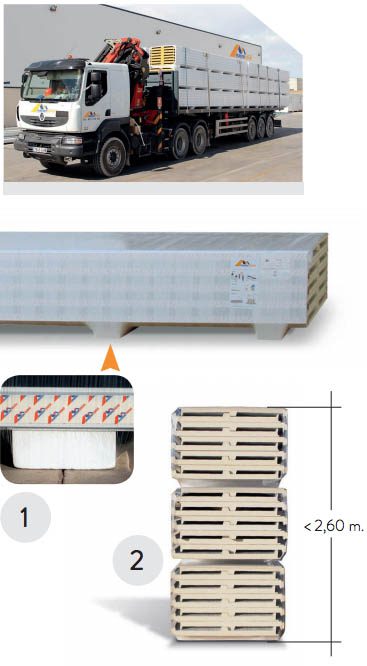

- Panels must always be transported on flatbed vehicles.

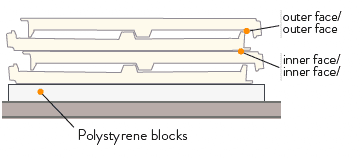

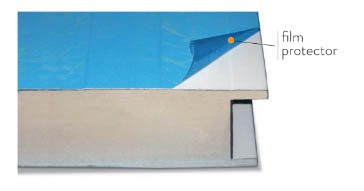

- Panels will always be packed with polystyrene blocks at the base to avoid damage.

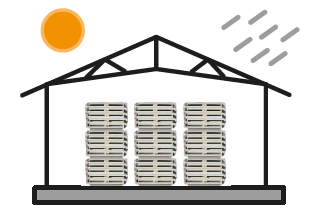

- Panel stacks should never exceed 2.60 m. high (including polystyrene blocks, accessories, cover caps, trims, etc).

By truck

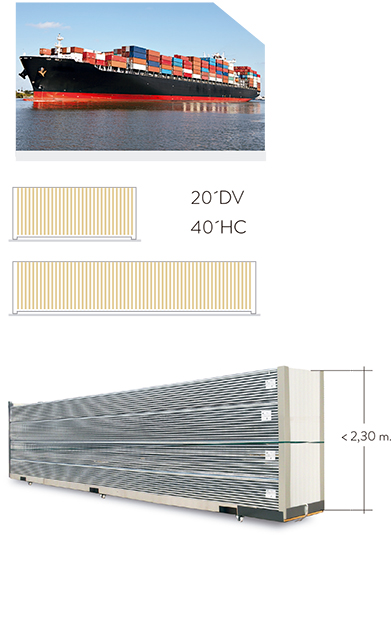

In containers

PANEL CONSTRUCTION DETAILS

MASTERPANEL provides its customers with a technical department to support designers and site management. We offer support for our construction system from the gestation of the project to its installation and subsequent maintenance.

This advice may include:

- Proposal of appropriate technical solutions for each project.

- Offering support in exploded views, quantifications of the necessary panels and accessories.

- Support and technical information for the training of installers.

- We provide plans and sketches of the most common technical details.

- Technical support in the correct installation of our panels, forming a team with the site management.

Colour chart

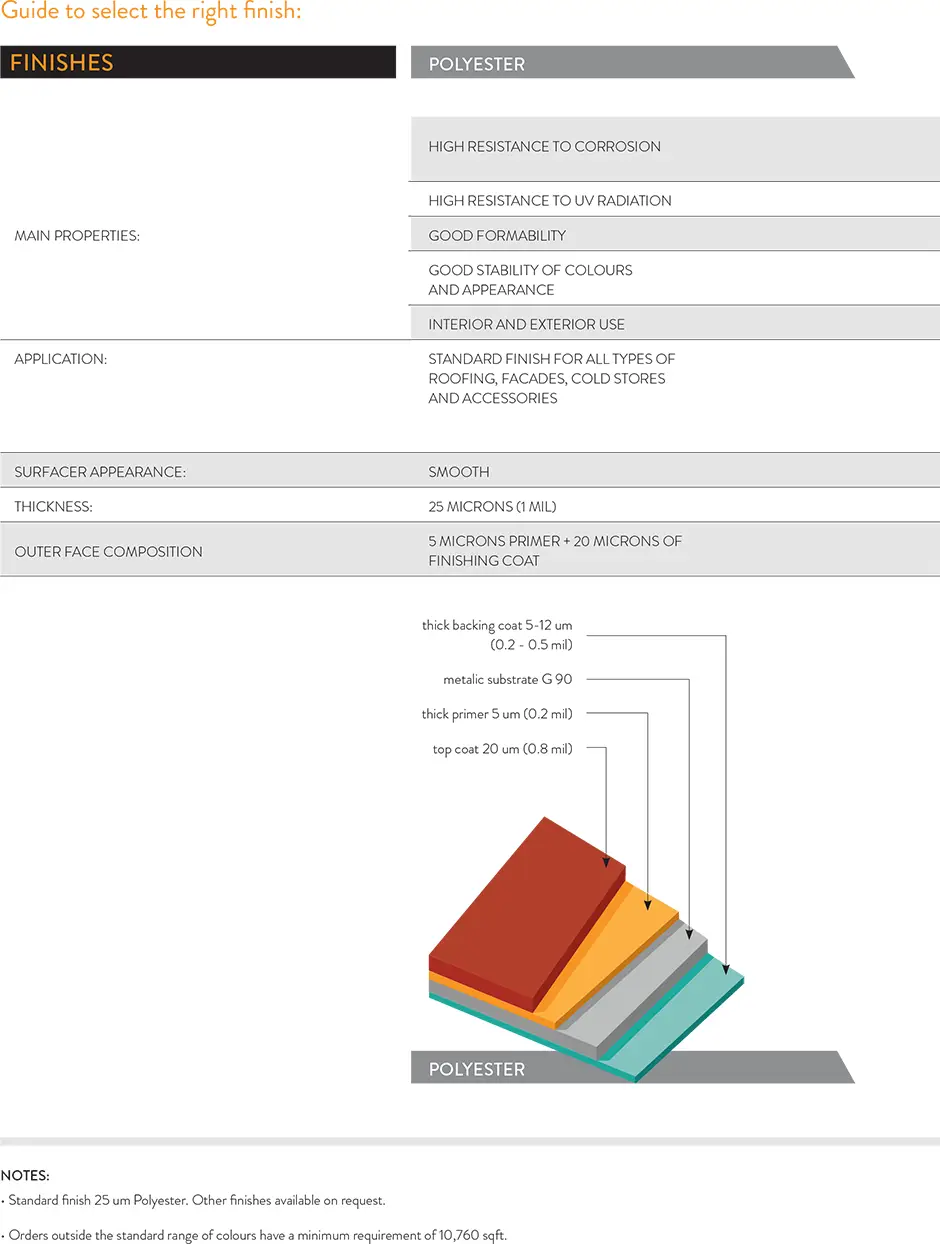

Guide to select the right finish:

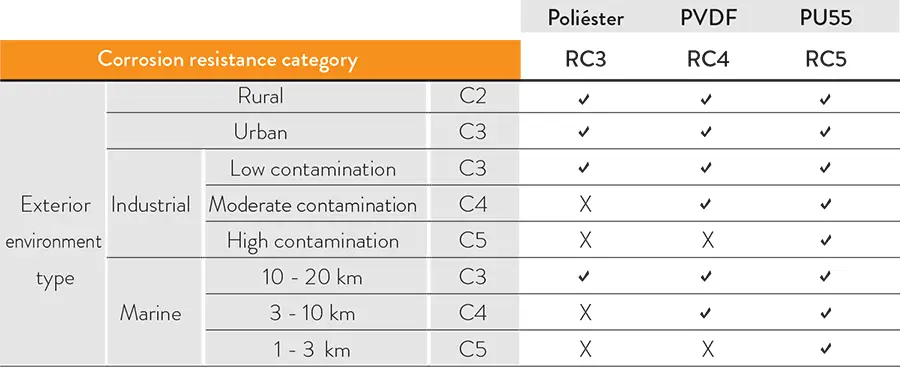

In order to choose the right prepainted finish for each use, the planner responsible for the design of the project must take into account both the incidence of UV rays and the exposure to corrosive environments of the building or project.

- Corrosion resistance of the paint system

To determine the corrosion resistance of a paint system, it is subjected to the salt spray test. This test evaluates the appearance of corrosion after a number of hours in a saline mist chamber. The results provide each paint scheme with an RC corrosion resistance value, from RC1 to RC5, with RC1 being the lowest value. This means that those RC3 rated paint schemes have shown their suitability for environments rated C3 or lower. - Resistance to UV radiation of the paint system

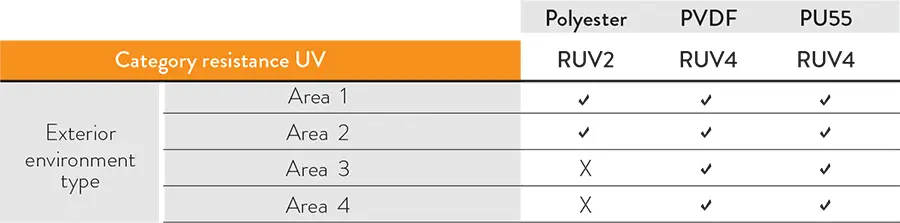

To determine the UV resistance of a paint system, it is subjected to the QUV accelerated aging test. This test evaluates the loss of gloss and colour over time due to UV rays. The results provide each paint scheme with a UV resistance value RUV, from RUV1 to RUV4, with RUV1 being the lowest value. - Classification of environments

| DESCRIPTION OF CORROSIVE CATEGORIES FOR EXTERNAL ENVIRONMENTS | |

| C1 | Very low. |

| C2 | Low: Areas with low level of contamination. Mainly rural or industrial areas without incidence by sulphur dioxide. |

| C3 | Moderate: Urban and industrial areas with low sulphur dioxide (SO2) pollution and coastal areas with low salinity (from 10 km to 20 km from the sea). |

| C4 | High: Industrial areas with moderate contamination by sulphur dioxide (SO2) and coastal areas with moderate salinity (from 3 km to 10 km from the sea). |

| C5 I | Very high: Industrial areas with very aggressive atmospheres and high contamination by sulphur dioxide (SO2) |

| C5 M | Very high: Coastal and maritime areas with high salinity (from 1 km to 3 km from the sea). |

| Corrosive environment category |

Environment type | |||||||||||

| Rural | Urban | Industrial | Marine | |||||||||

| C1 - very low | ||||||||||||

| C2 - low | ||||||||||||

| C3 - moderate | SO2 low | (10-20 km) | ||||||||||

| C4 - high | SO2 moderate | (3-10 km) | ||||||||||

| C5 I - very high | SO2 high | |||||||||||

| C5 M - very high | (1-3 km) | |||||||||||

| DESCRIPTION OF THE CATEGORIES OF UV RESISTANCE FOR EXTERNAL ENVIRONMENTS | |

| Area 1: | Areas with low exposure to UV radiation or without special colour maintenance requirements. |

| Area 2: | Areas with low exposure to UV radiation or without special colour maintenance requirements. |

| Area 3: | Areas with moderate exposure to UV radiation. |

| Area 4: | Areas with high exposure to UV radiation or with special colour maintenance requirements. |

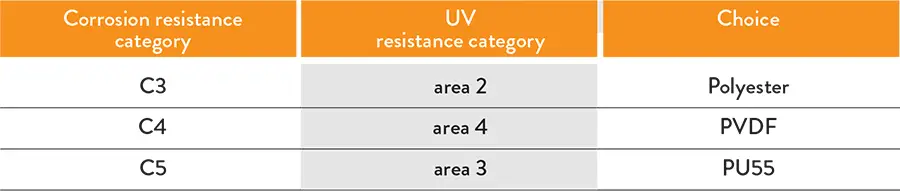

- Choice of finishes for different environments

Once the category of the environment is known, the person responsible for the design must decide on the painting system:

- The suitable paint system needs to be determined in terms of corrosion. The following table can be used as a guide.

- The suitable paint system in terms of UV radiation have to be determined. The following table can be used as a guide.

- A suitable paint system should be chosen in terms of both corrosion resistance and UV resistance. The following cases can be used as a guide.

The data stated in the tables is informative and does not constitute a guarantee of the material. You should contact Masterpanel about any applications which require a guarantee for the steel in the panels.