Refrigeration panels. Cold Room Panels

- Cold-room panels | Master Frigo

- Technical specifications

- ASSEMBLY AND ERECTION

- Finishes and colour chart

- Downloads

- Handling and maintenance

MASTER-FRIGO panels are continuous production line prefabricated panels, and are composed panels are Insulated Metal Panels composed of steel skins laminated to a minimum of 1.6inch polyisocyanurate foam core (min 2.3 pcf density).

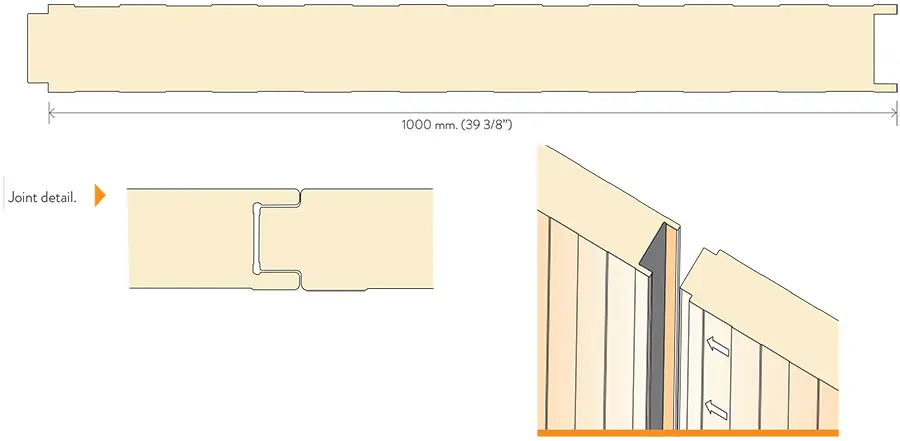

MASTER-FRIGO panels have a tongue and groove joining system are specially designed for use in all types of projects related to refrigeration industry, like the agro-food industry for refrigerated transport and storage of frozen and deepfrozen food.

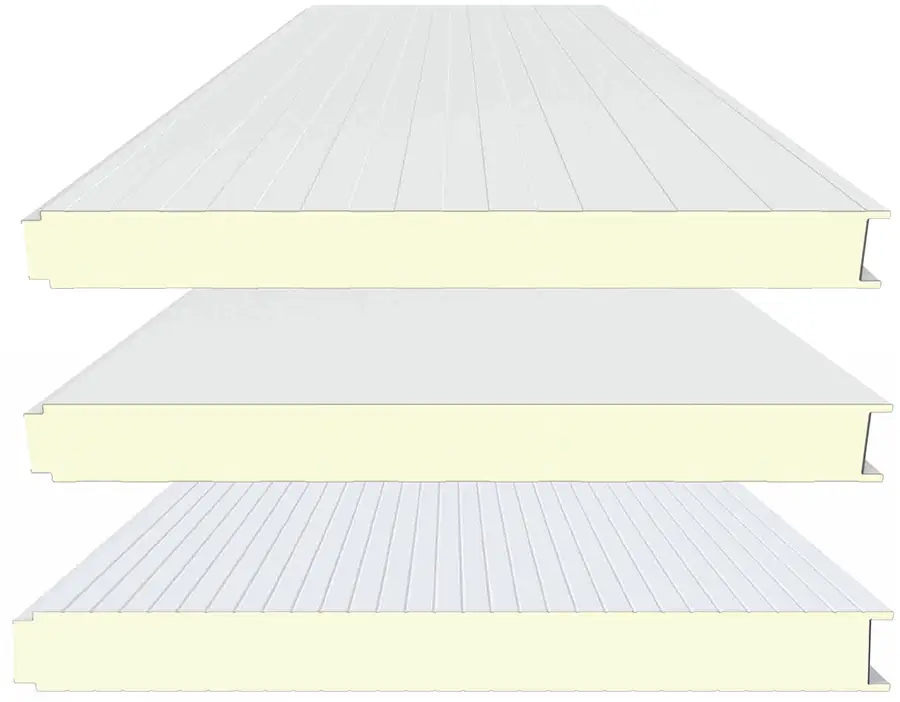

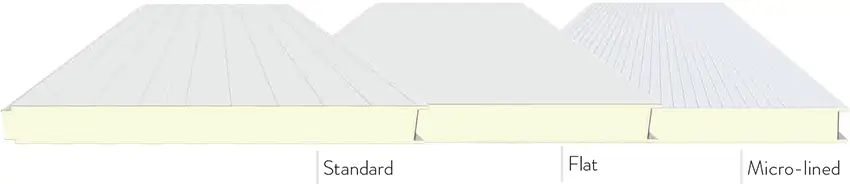

MASTER-FRIGO panels are available in seven different thicknesses. They come in three different exterior finishes (standard, flat and micro-lined) and three different interior finishes (standard, flat and micro-lined), as well as a wide range of available colours.

Technical specifications

| Panel thickness | 40, 50, 60, 80, 100, 120, 150 mm. 1 9/16, 1 31/32, 2 3/8, 3 5/32, 3 15/16, 4 23/32, 6, inch. |

| Cover Width | 1.000 mm. (39 3/8”) |

| Length | Up to 11.900 mm. (39 ft.) |

| Field of application | Cold room |

| Outer face thickness: | mm 0.5 / 0.6 / 0.7 |

| Inner face thickness: | GAUGE 26 / 24 / 22 |

| Exterior face: | G90 galvanized or AZ50 aluminium-zinc, coated steel in 26 GA and above |

| Interior face: | G90 galvanized or AZ50 aluminium-zinc, coated steel in 26 GA and above |

| Coatings (see section on Finishes): |

|

| Outer ribbing | Standard / Flat / Micro-lined |

| Inner ribbing | Standard / Flat / Micro-lined |

| Core type | Polyisocyanurate (PIR) |

| Core Density | 40 kg/m³ (+/- 10%) (2.3 PCF) |

| Panel thickness | Panel weight | U-Value | R-Value | |

| mm | inch | PSF | BTU/Hr ft2 0F | Hr ft2 0F/BTU |

| 40 | 1 9/16 | 2.06 | 0.100 | 9.96 |

| 50 | 1 31/32 | 2.14 | 0.079 | 12.72 |

| 60 | 2 3/8 | 2.22 | 0.064 | 15.66 |

| 80 | 3 5/32 | 2.38 | 0.047 | 21.26 |

| 100 | 3 15/16 | 2.55 | 0.037 | 26.73 |

| 120 | 4 23/32 | 2.71 | 0.031 | 32.15 |

| 150 | 6 | 2.96 | 0.025 | 40.21 |

Calculations according to EN14509, measuring the surface resistance according to horizontal flow and omitting the influence of the profiled faces. Losses in bolted connections must be calculated by the designer.

FUNCTIONS AND BENEFITS OF MASTER-FRIGO PANELS

- Aesthetically appealing

- Efficient thermal insulation capacity

- High mechanical strength

- Exceptional dimensional stability

- Watertight against water vapor

- Resistant to aggressive environments

- A versatile material that allows any configuration

- Quick to install and easy to maintain (easy to clean)

- Easily removable and can be reused

- Made-to-measure, avoids waste

- Made with recyclable materials

REACTION TO FIRE

Testing and approvals:

Master panel cold-room panels the most demanding requirements. We have large experience in producing insulated metal panels in our continuous production line.

| TEST | TEST METHOD | RESULTS |

| FIRE | ASTM E 84 | Flame spread index 20 Smoke developed index 300 |

| Strength | ASTM E 8 | > 32 ksi steel |

ASSEMBLY AND ERECTION OF COLD ROOMS

Basic assembly instructions:

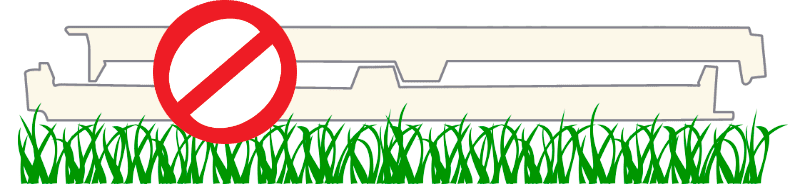

- The ground on which the insulated metal panels are to be set up should be completely flat, clean and smooth.

- Once the panels are installed, the verticality (walls) and horizontality (ceilings and roofs) should be checked, and any deviations corrected.

- The system of vertical jointing between panels is effected by pressure on the tongue and groove joint, with the panels being brought flush to each other.

- The wall–ceiling junction should be carried out strictly following the instructions provided, with special attention being paid to cuts that are made, when these may be necessary, to create the junction.

- When the joint between panels does not by itself have sufficient capacity to prevent the formation of condensation or ice, a sealant is applied in that area; this could be silicone (for air and water tightness), butyl (for water vapour tightness) or foam injected on site (to reduce the thermal bridge between the panels).

- The fixing of roof panels attached to building structures should be performed using connector rods or guy wires. The building structure must be designed to withstand both its usual loads and those due to the weight

of the panels themselves. - Refrigerating equipment and accessories must not be directly hung from the panels, but require a separate support system.

- Refrigerating equipment and accessories must not be directly hung from the panels, but require a separate support system.

- Avoid the use of cutting discs, as these may produce metal shavings which can stick to the panel surfaces and cause oxidation problems. If cutting discs must be used, ensure the complete removal of all metal shavings.

- Check that appropriate screws for the required structure are

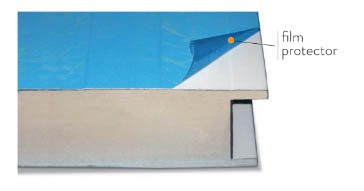

used. - Remove the protective plastic film from the panels.

- Ensure that any possible scratches that may occur on the outer face are correctly repaired.

- Check that individual points are properly sealed.

MAINTENANCE GUIDELINES FOR COLD ROOM

- The condition and tension of the ceiling fastenings tensors must be checked as well as cleaned every six months.

- The panel surfaces can be washed with a mixture of tap water and a neutral agent, then rinsed with running water and dried.

- Check the water collection channels once a year, ensuring that they are clean and in good condition.

- Check the condition of the sealing elements once a year.

Colour chart

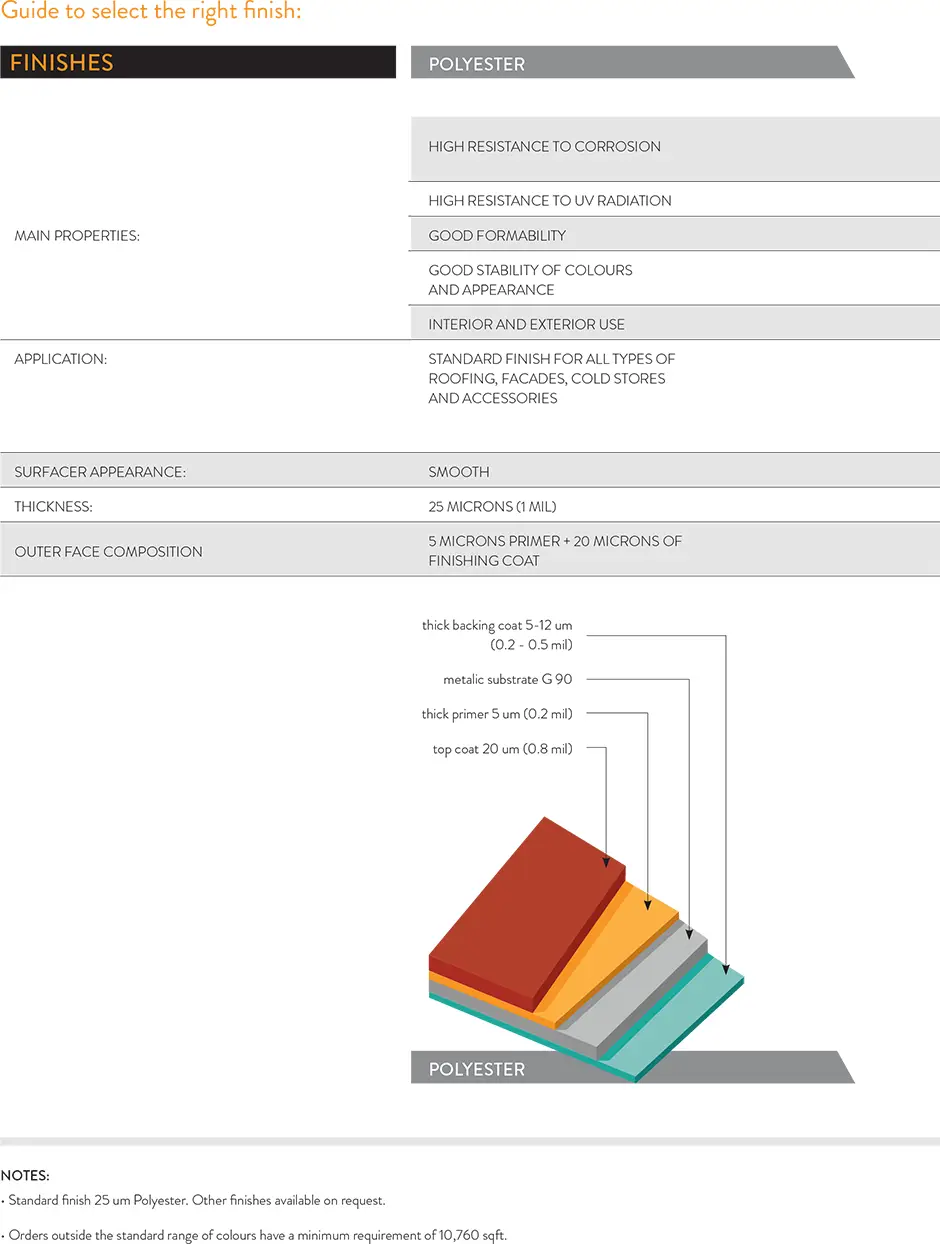

Guide to select the right finish:

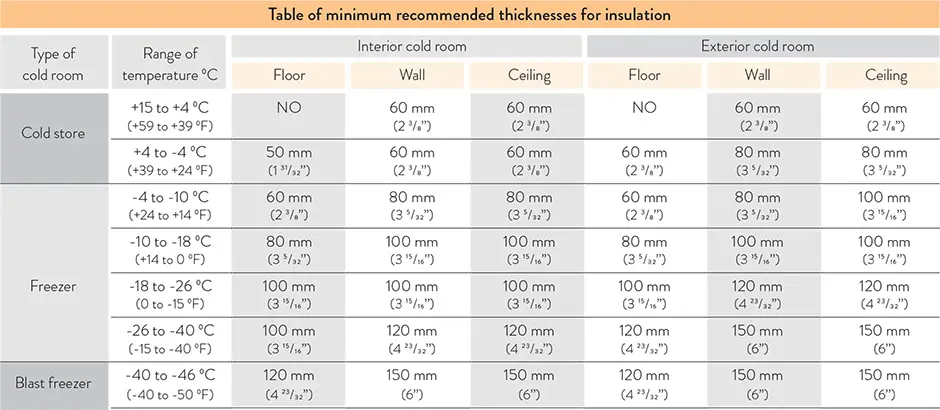

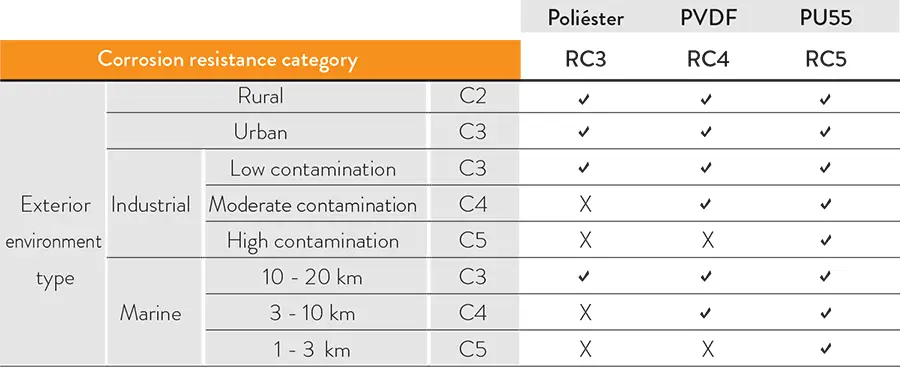

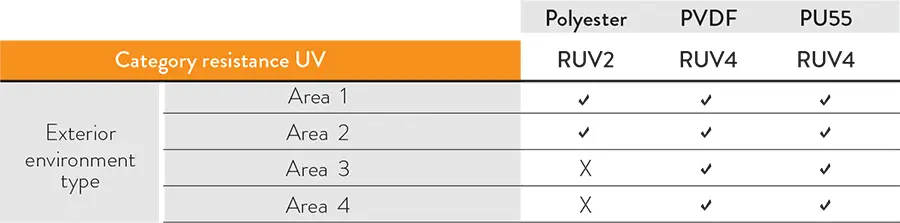

In order to choose the right prepainted finish for each use, the planner responsible for the design of the project must take into account both the incidence of UV rays and the exposure to corrosive environments of the building or project.

- Corrosion resistance of the paint system

To determine the corrosion resistance of a paint system, it is subjected to the salt spray test. This test evaluates the appearance of corrosion after a number of hours in a saline mist chamber. The results provide each paint scheme with an RC corrosion resistance value, from RC1 to RC5, with RC1 being the lowest value. This means that those RC3 rated paint schemes have shown their suitability for environments rated C3 or lower. - Resistance to UV radiation of the paint system

To determine the UV resistance of a paint system, it is subjected to the QUV accelerated aging test. This test evaluates the loss of gloss and colour over time due to UV rays. The results provide each paint scheme with a UV resistance value RUV, from RUV1 to RUV4, with RUV1 being the lowest value. - Classification of environments

| DESCRIPTION OF CORROSIVE CATEGORIES FOR EXTERNAL ENVIRONMENTS | |

| C1 | Very low. |

| C2 | Low: Areas with low level of contamination. Mainly rural or industrial areas without incidence by sulphur dioxide. |

| C3 | Moderate: Urban and industrial areas with low sulphur dioxide (SO2) pollution and coastal areas with low salinity (from 10 km to 20 km from the sea). |

| C4 | High: Industrial areas with moderate contamination by sulphur dioxide (SO2) and coastal areas with moderate salinity (from 3 km to 10 km from the sea). |

| C5 I | Very high: Industrial areas with very aggressive atmospheres and high contamination by sulphur dioxide (SO2) |

| C5 M | Very high: Coastal and maritime areas with high salinity (from 1 km to 3 km from the sea). |

| Corrosive environment category |

Environment type | |||||||||||

| Rural | Urban | Industrial | Marine | |||||||||

| C1 - very low | ||||||||||||

| C2 - low | ||||||||||||

| C3 - moderate | SO2 low | (10-20 km) | ||||||||||

| C4 - high | SO2 moderate | (3-10 km) | ||||||||||

| C5 I - very high | SO2 high | |||||||||||

| C5 M - very high | (1-3 km) | |||||||||||

| DESCRIPTION OF THE CATEGORIES OF UV RESISTANCE FOR EXTERNAL ENVIRONMENTS | |

| Area 1: | Areas with low exposure to UV radiation or without special colour maintenance requirements. |

| Area 2: | Areas with low exposure to UV radiation or without special colour maintenance requirements. |

| Area 3: | Areas with moderate exposure to UV radiation. |

| Area 4: | Areas with high exposure to UV radiation or with special colour maintenance requirements. |

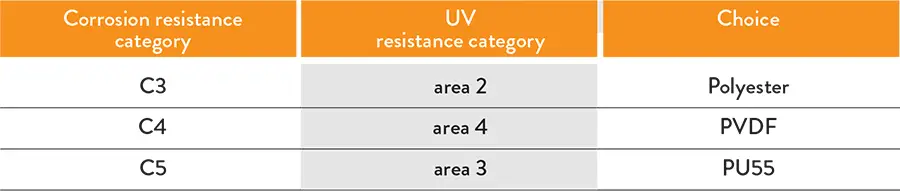

- Choice of finishes for different environments

Once the category of the environment is known, the person responsible for the design must decide on the painting system:

- The suitable paint system needs to be determined in terms of corrosion. The following table can be used as a guide.

- The suitable paint system in terms of UV radiation have to be determined. The following table can be used as a guide.

- A suitable paint system should be chosen in terms of both corrosion resistance and UV resistance. The following cases can be used as a guide.

The data stated in the tables is informative and does not constitute a guarantee of the material. You should contact Masterpanel about any applications which require a guarantee for the steel in the panels.

In order to provide you with information about this product, we offer you all the documentation concerning Master-Frigo / Cold room.

MasterPanel offers our clients a technical department to support your designers and Project Management. Our building system section provides support from the initial concept of the project to the installation and subsequent maintenance.

- Proposals for appropriate technical solutions for each project.

- Providing support regarding the cutting, quantifications of the panels and necessary accessories.

- Support and technical information for the training of fitters.

- We provide plans and sketches of the most common technical details.

- Technical support in the correct installation of our panels, forming a team with the Project Management

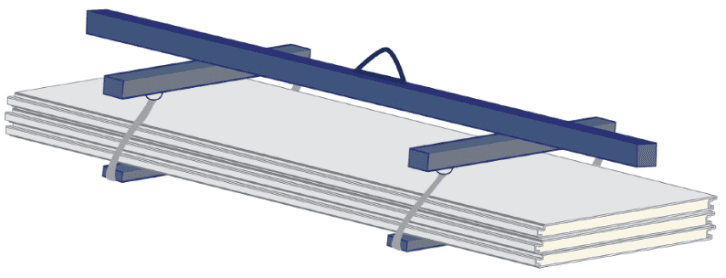

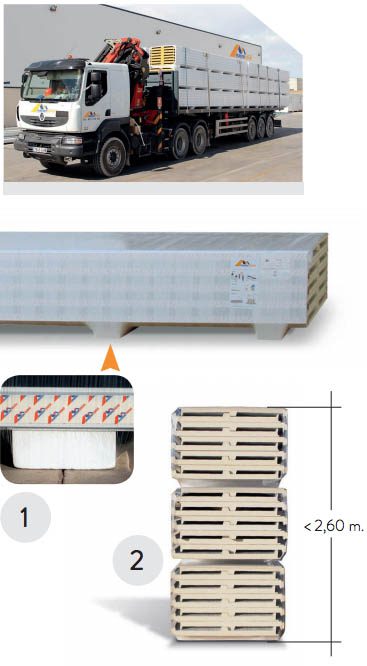

- Panels must always be transported on flatbed vehicles.

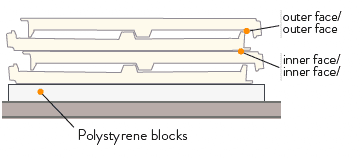

- Panels will always be packed with polystyrene blocks at the base to avoid damage.

- Panel stacks should never exceed 2.60 m. high (including polystyrene blocks, accessories, cover caps, trims, etc).

By truck

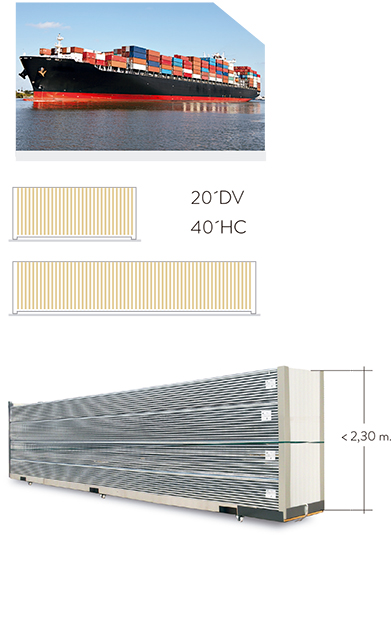

In containers